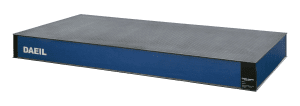

Optical Tables

Built for Science

Ever since 1993, DAEIL SYSTEMS has been designing and manufacturing optical tables. Our optical tables are

designed for challenging applications that are susceptible to vibration like optical experiments, spectroscopy,

interferometry, holography, microscopy, nano-positioning, etc. The lightweight but incredibly rigid steel honeycomb

table top is combined with uniquely designed pneumatic vibration isolators, significantly reducing vibration.

Why do we need optical tables?

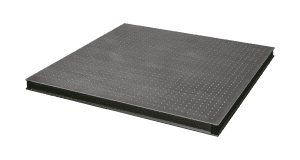

An optical table is a vibration isolated platform, specially designed to support applications of photonics and laser and to isolate the various sources of vibration

that disturb optics and laser related experiments and metrology. The optical table top is designed to be as stiff as possible to minimize relative motion between

existing optical elements that are mounted on the optical table top. The high-performance pneumatic isolators reduce floor vibrations and provides effective

damping to restrict the amplitude of vibrations at resonance.

The primary goal of an optical table

Static Rigidity

Static rigidity defines the ability of an optical table top to minimize deflections and relative motion between components when a static load is placed on the table top. Therefore, the higher static rigidity contributes to maintain the precise and better alignment of the elements, as a result, the system performance will not be disturbed. Moreover, the higher static rigidity is highly correlated with a high natural frequency of the table top, preventing the coincidence with low frequency vibrations that are not reduced by vibration isolators.

Dynamic Rigidity

Dynamic rigidity defines the ability of an optical table top to resist deflection in response to external forces such as floor vibration, acoustic noise and mechanical

sources on the surface of the optical table top. The optical table top with the higher dynamic rigidity damps the structural resonance due to the floor vibrations

passed through pneumatic isolators.

Vibration Isolation

Pneumatic isolators of the optical table reduce the floor vibration before it is transmitted to the table top surface. When the forced frequency vibration is lower than the natural frequency of the isolators, vibration is transmitted directly to the table top. When the forced frequency vibration coincides with natural frequency of the isolators, vibration is amplified. Thus, it is critical to design the isolators with the lower natural frequency.

Damping is another essential factor when designing pneumatic isolators. Damping decreases the amplitude of vibration caused by resonance, improving the system stability and providing the fast settling time.